NEWS

Increasing the grain cleaning performance

To ensure optimal grain cleaning performance, several adjustments have been made and processes optimised.

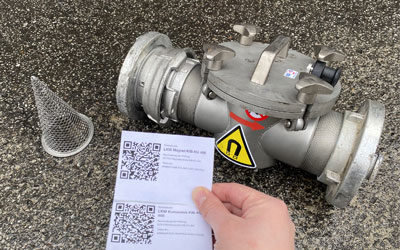

More safety through magnets

When it comes to food safety, we take no risks. Now we go one step further in addition to the safety measures in production: until now, the safety measures for the vehicles were the cone sieves. Now we have also equipped our entire fleet with finger magnets with a strength of 10,000 gauss.

Sustainability and environmental protection

Our malthouse consumes an enormous amount of water due to production, cleaning and disinfection after each batch.

Process optimisation and expansion of silo capacities

With a focus on customer satisfaction, we are constantly optimising our processes.

Audits with distance

Audits serve the purpose of safety and this topic is accordingly very important to us as a food manufacturer! That’s why, with the start of the Corona era, we immediately looked for ways to have all audits take place and have been offering them remotely.

Inside and outside up to date

After extensive modernisation and conversion measures as well as constant optimisation of our processes in the mill and malthouse, we now want to show this to the outside world as well.

Live and virtual: tour of the malthouse and mill laboratory

New times – new ideas. We are very pleased to be able to show the members of the VdB (Association of the Baking Industry) our malthouse via a virtual live tour on 1 September!

Harvest report 2020

Key figures and processing recommendations for wheat and rye

Delivery guarantee for our bakers and food producers

The shorter the delivery routes, the longer the supply.

Easy detection of critical control points

With the implementation of the “CCP-Check” app, we have had a secure and smart solution since the beginning of August 2019.

Food Ingredients Europe 2019

Visit us from 3rd to 5th December 2019 in Paris!

Seamless tracing

back to the pallet

Instagram News

FI Europe Frankfurt 🏢

Vom 19. - 21. November 2024 findet die diesjährige FI Europe in Frankfurt statt. Und wir sind als BiGu Mühlengruppe dabei!

Die Messe für Lebensmittelzutaten bringt so ziemlich alle bekannten „Geschmacksmacher“ zusammen und bietet sie ein voll gepacktes Programm mit interessanten Vorträgen, Diskussionen, Wettbewerben, Verkostungen und vielem mehr!

Wer an unserem Stand vorbeischauen möchte, findet diesen unter der Nummer 4.1A30. Wir freuen uns auf gute Gespräche! 😊

Auf unserer Silo-Baustelle 🏗️ geht es weiter voran - oder besser gesagt aufwärts! 😉

Das neue Gebäude hat mittlerweile eine Höhe von knapp 20 Meter erreicht. Das erste Drittel ist somit geschafft 🤩.

Vor wenigen Tagen konnte die Decke des unteren Abschnitts sowie die Schalung der Silos abgeschlossen werden. Wir sind schon gespannt auf die weitere Entwicklung und werden den Fortschritt weiter mit Euch teilen! 😊

Unser Mehl-Lager 😍

In unserem letzten Post haben wir Euch einen kleinen Einblick in die lose Verladung unseres Mehl gegeben. Das Pendent dazu spielt sich gewissermaßen in unserem Logistikzentrum ab.

Hier wird Mehl in Gebinden verschiedener Größen verpackt, zwischengelagert und zum Abtransport vorbereitet. Wer sich unter „Lager“ nun einen Bereich vorstellt, der weitestgehend still steht und wenig dynamisch ist, geht fehl. Denn das Lager für unser Mehl ist ständig in Bewegung! 💪🏻

Kaum sind die fertigen Paletten im Lager, werden sie wenige Zeit später schon wieder in LKWs weiterverfrachtet und zu Kunden gefahren 😊.

Verladung 🚛

Um unsere Kunden täglich mit Mehl aus unserer Mühle versorgen zu können, bedarf es einer leistungsstarken Verladung. Denn der Großteil unseres Mehls wird nicht nur in Kilo-Gebinden oder Big-Bags geliefert, sondern lose!

Für die Lose-Verladung fährt der Tankwagen in die sogenannte Verladesiloanlage und „tankt“ in kürzester Zeit 25 Tonnen Mehl. Dabei ist es wichtig, die Ladung von äußeren Einflüssen zu schützen!

Sodann muss das Mehl nur noch heile zum Kunden gebracht zu werden 😊.